Noise in hospitals

Noise levels have steadily increased in hospitals over the last >40 years, both daytime and nighttime [1]. The noise level in operating rooms can be particularly difficult and research shows that this may affect the ability of the staff to perceive proper oral instruction; it also affects their perceived stress and well-being. Comparatively sound peaks can reach 110dB when a saw and drill are in use [2, 3]. Acoustics in operating rooms can be specifically troublesome.

Kracht, Busch-Vishniac, and West showed, in a study from 2007 in Johns Hopkins Hospital, that orthopedic surgery was found to have the highest Leq at approximately 66 dB(A). Neurosurgery, urology, cardiology, and gastrointestinal surgery followed closely ranging from 62-65 dB(A). For neurosurgery and orthopedic surgery peak levels exceeded 100 dB over 40% of the time [4].

What can be done to reduce this noise? It requires a combination of actions; alteration of human behavior, settings, and functional sounds on the med-tech devices and sound-absorbing materials to deal with excess sound energy and unwanted reflections [5].

Therefore sound-absorbing material can improve the sound environment as shown in several studies and the effect has an impact on both the staff work environment, well-being, and stress as well as the patient experience of received care [6,7].

Building with partitions/modules

The latest way of building operating rooms is to use modular partitions. Every operating room is custom-made with the technology and displays integrated into the module unit. This gives maximum use of the surface and is functional and hygienic. Building time is heavily reduced, noise at the construction site decreases and there is less dust and spillage.

These are important factors as new operating rooms often are built in conjunction with the existing and everyday work is still ongoing next door. However, there is a challenge here – materials used for the walls and ceiling are often highly reflective of sound, and reverberation time is way exceeding the limits!

Project

In this project, we worked with two operating rooms in Malmö, Sweden, at an orthopedic operating unit. Two ORs at 62 m2 and supporting areas made a total of 350 m2. The module supplier was Young Medical (NL) provided by distributor Meditek (SE). Corian was used in the partitions for the wall and the ceiling was changed from Corian to a sound-absorbing ceiling from Ecophon (glass mineral wool).

Orthopedic surgery is one of the most sensitive to microbial pollution and the top-range product Ecophon Hygiene Advance™ was chosen as it can be disinfected daily if needed, and is classified ISO 3 according to ISO 14644-1 [8]. Thus supporting the goal of <5 CFU (colony forming units) in the operating site area.

The sound-absorbing ceiling was assembled as a comprehensive ceiling solution except for the ventilation, pendants, and lighting, giving coverage of approximately 85% of the total ceiling area. No absorbers were mounted on the wall. The absorbers were assembled in an Ecophon grid system withstanding frequent disinfection.

The advanced ventilation system “Opragon”, functioning as a temperature airflow system, was chosen. The ventilation system can be seen as a large circle in the ceiling with 8 cones. As seen in the picture both the ventilation system, lighting and pendants reduce the amount of sound-absorbing ceiling tiles in the room.

Acoustics

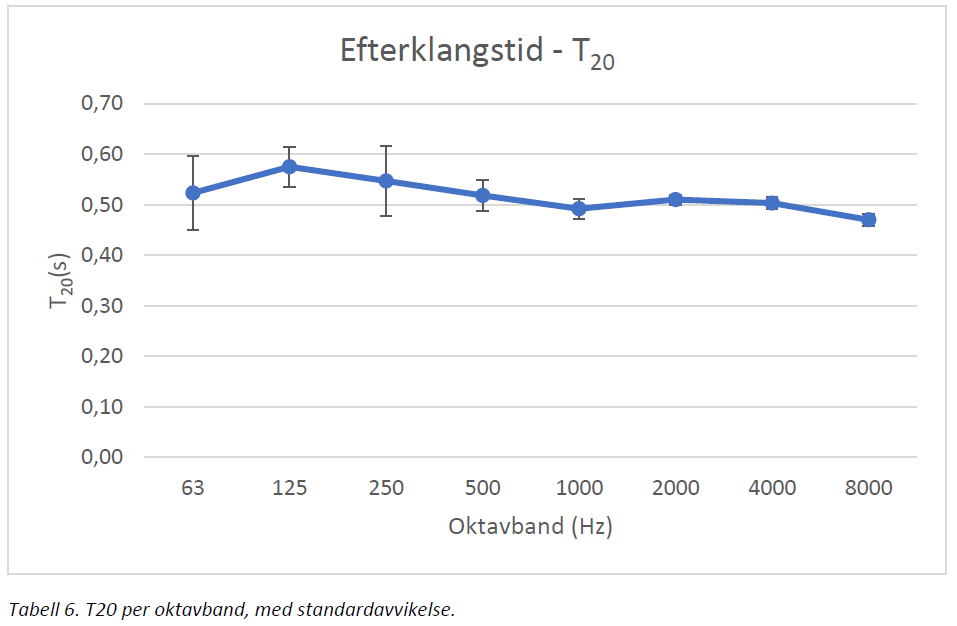

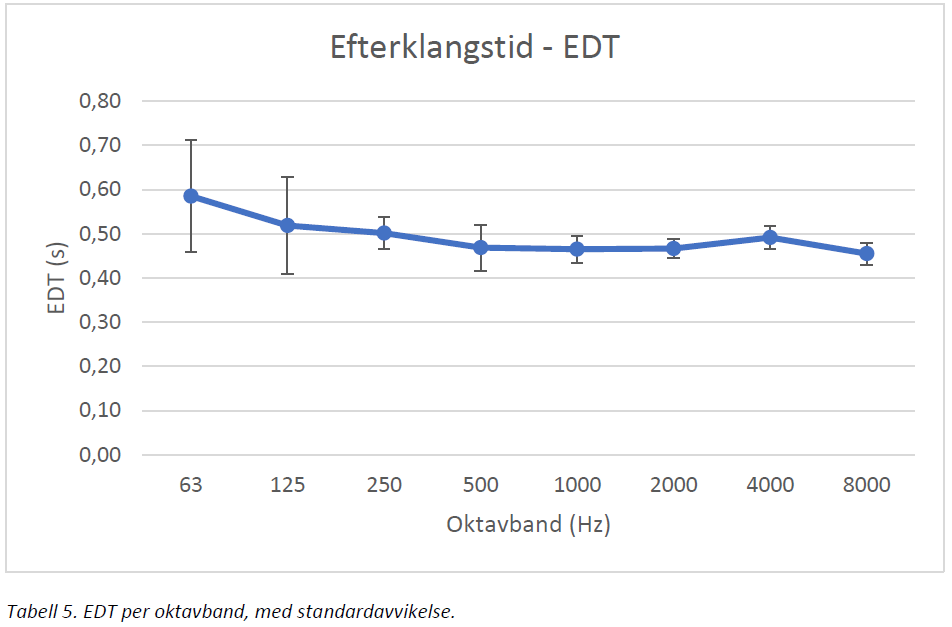

So how did we do? Or let´s start at the other end. The required reverberation time is ≤0,6 seconds (250-4000Hz) and 0,8 seconds at 125Hz according to SS 25268 building regulations for hospitals [9]. We could already by entering the room feel that the sound environment was good so expectations were high. And this is how it looked:

And Yes – as you can see the results were very good! Reverberation time shows a mean of 0,5 seconds and 0,6 seconds at 125Hz. We couldn’t be happier with the result!

The reverberation time is mainly influenced by the surface treatment of the room. A long reverberation time can be experienced with the room sounding sonorous or echoing, while a short reverberation time can be felt like the room sounds subdued. We are very confident that this operating room has the very best conditions of reverberation time possible!

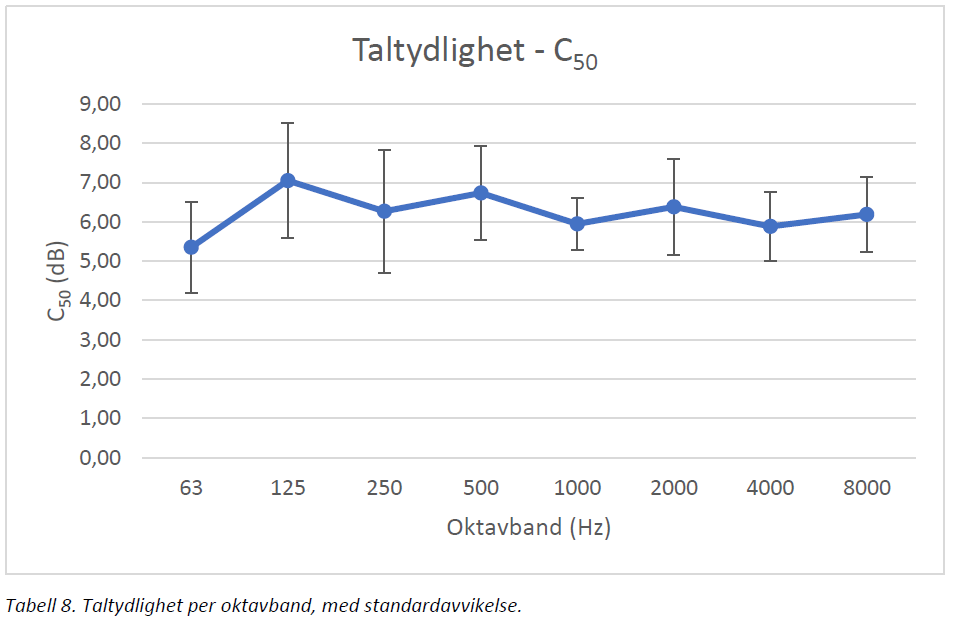

C50

To gain a better understanding of the work environment we also chose to measure Speech Clarity (C50), even though it is not included in the standard.

And C50 also measures well as shown above. The aim for good speech intelligibility is generally considered 6dB or higher. A high C50 is strongly related to speech intelligibility, this being our brain integrating the early reflexes and joining them with the direct sound, which makes us perceive the sound stronger and with better clarity. A high C50 is especially important in the frequency range 500-4000Hz where a large amount of information-bearing consonants in our voices are present.

Clarity is primarily influenced by the design and layout of the room. It is also strongly affected by the proportion of reflective surfaces that are in direct proximity to the source of the sound. The amount of diffusing material such as pendants and machinery also influences speech intelligibility.

The new operating rooms opened on May 18th, 2020 and we are all looking forward to hearing about the staff experience when they have worked in the facilities for some time. But that’s a different story!

Want to know more about the project? Don´t hesitate to contact me:

Maria Quinn, Concept Developer Healthcare & Reg. Nurse

Maria Quinn, Concept Developer Healthcare & Reg. Nurse

_________________

References:

[1] IJ. Busch-Vishniac, JE. West, C. Barnhill, T. Hunter, D. Orellana, R. Chivukula: Noise levels in Johns Hopkins Hospital. J Acoust Soc Am. 2005;118:3629–3645.

[2] Sentinel Event Alert Issue 50: “Medical device alarm safety in hospitals” A complimentary publication of Issue 50.The Joint Commission, 2013.

[3] EE. Ryherd, S. Okcu, J. Ackerman, C. Zimring, K. Persson Waye: “Noise pollution in hospitals: Impacts on staff”, J. Clin. Out. Mgmt. 2012, vol 19, no 11, p491-500

[4] JM. Kracht, IJ. Busch-Vishniac, JE. West: Noise in the operating rooms of Johns Hopkins Hospital. J Acoust Soc Am. 2007;121:2673–2680.

[5]. Engelmann CR, Neis JP, Kirschbaum C, Grote G, Ure BM. A noise reduction program in a pediatric operation theatre is associated with surgeon’s benefits and a reduced rate of complications: a prospective controlled clinical trial. Ann Surg. 2014;259:1025–1033.

[6]. MacLeod M, Dunn J, Busch-Vishniac IJ, West JE, Reedy A. Quieting Weinberg 5C: a case study in hospital noise control. J Acoust Soc Am. 2007;121:3501–3508.

[7]. Blomkvist V, Eriksen CA, Theorell T, Ulrich R, Rasmanis G. Acoustics and psychosocial environment in intensive coronary care. Occup Environ Med. 2005;62:e1.

[8]. ISO 14644-1:2015. Cleanrooms and associated controlled environments – Part 1: Classification of air cleanliness by particle concentration.

[9]. Swedish Standard Institute. SS 25268:2007 Acoustics – Sound classification of spaces in buildings –Institutional premises, rooms for education, preschools and leisure-time centers, rooms for office work and hotels