Modular operating rooms

Building a hospital is a complex task to do and especially operating rooms can be a challenge. The functionality of the room has to be ‘spotless’ as well as the cleanliness. In a lot of projects – both new buildings and renovations – modular operation rooms are used to secure a short, controlled, and precise building process. Modular rooms are often of high quality, robust, and have long durability.

There is however normally one disadvantage to modular solutions: all the surfaces in the room, including the floor, walls, and ceiling, absorb very little sound and thus impact negatively on the sound environment! This is because the modules are constructed from glass and metal, which instead of contributing to a calm sound environment cause challenges with acoustics.

Sundsvall Regional Hospital

In Sweden, in Sundsvall Regional Hospital – a new surgical center was to be built since the existing department was opened in the mid-1970s. The premises were in disrepair and could not meet modern demands for accessibility, hygiene, and a working environment. Many of the installations had also reached the end of their technical lifespan. Because of this knowledge, a preliminary study was carried out in 2013 to draw up new proposals for a Surgical Centre that would allow premises to be updated and equipment brought up to a standard that would safeguard its performance for many years.

Swedish Standard

According to Swedish Standard 25268, the reverberation time in operating rooms should not exceed 0.6 seconds. In bare form, without any further acoustic measures, the value for the modules is around 2.0 seconds (depending on room volume). It seemed as if the original construction of the module could not solve the acoustic challenges…

A long tradition of research shows that multiple acoustic descriptors are necessary to secure good room acoustics in educational, office, and healthcare facilities. Acoustic descriptors such as reverberation time (RT), Clarity (C50), Deutlichkeit/Definition (D50), and Room Gain (G) support low noise levels, good speech intelligibility, and sufficient signal-to-noise ratios. But in a lot of standards and building codes, we still see only reverberation time.

Including C50 and Room Gain

Maria Quinn, Concept Developer Healthcare at Saint-Gobain Ecophon, was involved in the project. She made some calculations on the modules using a class A hygienic glass wool acoustic ceiling instead of metal and the calculations showed big differences in comparison to the original metal constructions. Maria Quinn chose to include both C50 and Room Gain together with T20 to secure a more detailed evaluation of the room acoustics.

Because of these calculations, Sundsvall Regional Hospital agreed to be part of a pilot study where the original metal ceiling in the modules was changed to a glass wool product. They decided to try the new solution in both a ‘normal’ size operation room (60 m2) and a huge ‘hybrid operation theatre’ (105 m2).

Results

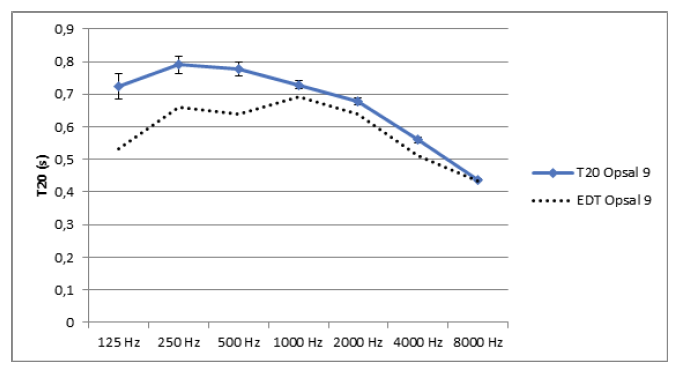

The two pilot rooms were measured after the installations and the results were close to the calculations done before the refurbishments. The average measured value was 0.7 seconds in the normal size OR. T20 is expected to drop slightly when all the equipment is in place. T20 also drops when people are in the room. Overall, the measurement may be considered to comply with the Swedish Standard.

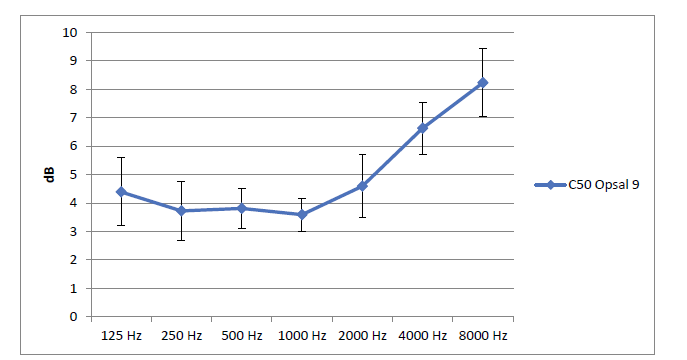

As mentioned earlier speech clarity is not a requirement in SS 25268, but to evaluate the acoustics in more detail this was included. Primarily to gain knowledge about how spoken communication in the operating room would be affected.

Speech clarity had an A-weighted sound level of 5.6 dB, which is close to what is usually aimed for (between around 6 and 10 dB) in a room where spoken communication is important. The operating room has relatively high speech clarity at the higher frequencies that carry consonant sounds. Important for speech perception. C50 is expected to rise slightly when people are present in the room. This is consequently an excellent result.

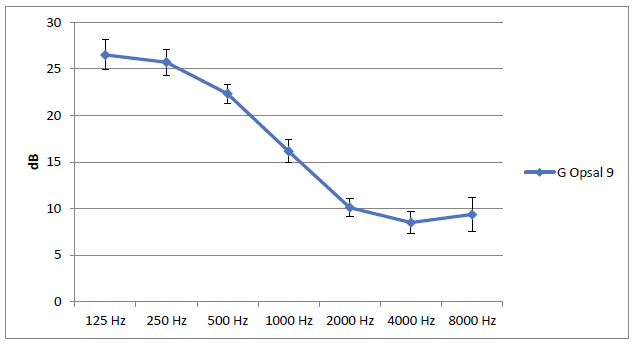

Room Gain values are very high for low frequencies in the operating room. A high value can be fatiguing, especially in an operating room that contains a lot of equipment and people, since this results in a high sound level. This is especially true when the value is high at low frequencies, as in this measurement.

Room Gain is often what challenges healthcare facilities regarding sound and acoustics. Because of high hygiene demands surfaces are often of hard material that does not absorb sound energy very well. This is an area that could benefit from product development in regards to absorbing wall panels that also reach high hygiene demands.

In the large hybrid operation theatre, the room acoustics are challenged – also because of the room size. The average measured value was 0.9 seconds. This room did not meet the T20 requirement which is why the project group has already planned to do the additional acoustic treatment.

Modular operating rooms – free download

You can download a brochure about the project in English here: BC Sundsvalls sjukhus_EN 20170929 – and in Swedish here: BC Sundsvalls sjukhus_Swedish

If you want to learn more about the project and modular operating rooms don’t hesitate to contact Maria Quinn at [email protected]